A few years ago, we had an idea to create a community launderette in Anfield/ Everton with affordable washing and drying facilitates as well as a space for people to gather, talk and learn.

We’re almost ready to open for business thanks to the hundreds of hours our small team have put in to renovating our space.

For our third blog our project coordinator Grace shares her experiences of bringing together the skills and knowledge of lots of different people to pull together a functioning launderette space

My name is Grace and I have been involved with Kitty’s Launderette since the early days, I’m responsible for a lot of the research and co-ordination of getting our idea off the ground. Since securing our building in Spring 2018, we have been working closely with a number of people and organiations to create a functioning top-quality launderette; which is accessible, safe and efficient. It’s taken a lot of planning, consultation and collaboration, pushing us all beyond our comfort zones, as many of us have never undertaken anything of this size and complexity before.

Throughout the planning process we were lucky to work with Alex from Lj Architects based in North Liverpool and Paul, our structural engineer. They’ve both given us that technical underpinning of the lay out of the space, ensuring we are complying with complex building regulations and fire safety standards. They have been incredibly supportive of what we are trying to achieve, investing and sharing our vision from the early days and helping us gain planning permission in December 2018.

Since the beginning of our project we have been thinking about how we could make our new set up as environmentally friendly as possible. After undertaking research into the industry, we took the decision to opt for a completely electric set-up for the water heating and drying. Gas is largely traditionally used for this and can be cheaper from suppliers however part of our reimagining of a launderette means it needs to be fit for a fossil free future so we’re very proud to be using a renewable energy provider.

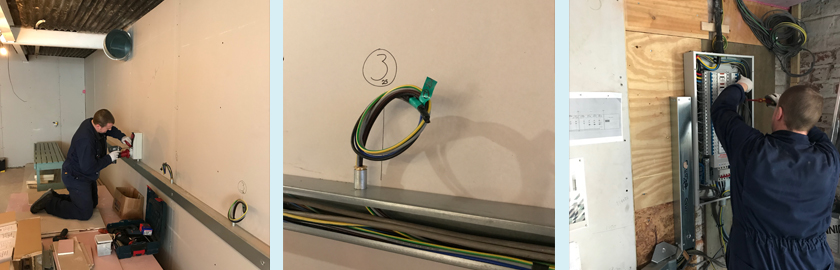

This meant that we definitely needed a brilliant electrician and thankfully we found one! Phil was responsible for undertaking a total refit of the space, installing powerful three phase sockets for our machines, trunking and a new large powerful fuse board; not to mention all the lighting and new sockets. Phil approaches every work day with a smile on his face and enthusiasm for his job. He has delivered the whole refit over a couple of months becoming a key member of the team and developing a good set of jokes with our lead builder Ehsan.

Alongside Phil, Ehsan has been working on the detailed insulation and fire boarding of the walls and ceiling. As the ceiling in particular can be quite challenging with several layers of heavy fire proof board, Ehsan (also known as the inventor) fabricated himself a plaster board lifting machine on wheels to assist him in this job.

Ehsan’s desire and ability to turn his hand to everything has meant, he built and installed our new electric roller shutters as well as the new higher capacity plumbing and drainage in the launderette space. He also ensured we made a great accessible toilet and baby changing facilities in the space for all visitors to use. He’s also installed plumbing to our all-important tea and coffee station!

A long- time friend of the laundry, Kenny resident and award-winning plaster, Yagob did an amazing job helping to plaster the launderette in just a couple of weekends. It was amazing to watch him work with such speed and precision and the final finish of the space is fantastic.

Since 2017 we have been researching the washing machines that we hoped to have in our new community launderette. Since we had the opportunity to build the launderette from scratch we wanted to get the most environmentally friendly machines on the market, with efficiency and quality manufacturing of great importance. We have been to visit loads of different launderettes around the country, talked to them about their experience of their machines and sought as much advice as we could possibly glean!

We have been thrilled to work alongside Goodman Sparks, a 30+ year old family business in Sheffield who have been incredibly generous to Kitty’s Launderette with their time and knowledge, helping us shape the best set up for the space and giving us the low-down on all the industry tips. They will be delivering the training to our new team so we can deliver the best quality laundry and eco dry cleaning services.

Machine delivery day finally arrived with great excitement and anticipation, we all had our fingers crossed (seriously) that all our measurements were correct and we got all the plumbing, electrics and ventilation in the right place! Goodman Sparks team did the install with Ehsan on hand for building support and cups of tea.

They are now all fixed into place, all the services connected and ready for us to now complete the design finishes’ in the space ahead of opening. We of course have begun doing some test washing to make sure they are working well, which is handy because we all have loads of dirty building clothes from the last months of hard graft! So, here’s to a spotless, clean smelling future!